Being a father of four, my number one priority as a parent was always the safety of my children. Especially when they are playing on the playground that has equipment higher than 5 feet. I have purchased many playground sets, swing sets, and trampolines. And every time my four boys would climb on any playground equipment my anxiety grew. I wasn’t worried about my sons climbing capabilities, I encouraged them to do that…. I was more worried about their falling capabilities.

Falling on surfaces that created injury and sometimes death has evolved over the decades. There are new standards to the industry when it comes to testing fall surfaces and each playgrounds safety requirements. IPEMA (international play equipment manufacturing association) has written guidelines and created safety requirements for the playground industry.

I was fortunate in the past to have been asked to help remodel and design new playgrounds for a private school that has playgrounds throughout many states. They spoke to me in compassion of how many children were being rushed to the nurse’s office and sometimes to the hospital. During this relationship I learned so much from the existing surfaces that I was to remove and replace with synthetic turf. I traveled to each playground surface and spent extensive time studying its surface and how I can help make it safer and better without the heavy maintenance that playground surfaces require. I studied Pea Gravel playgrounds, Wood Chip playgrounds, small and large Rubber Mulch playgrounds. I had not only witnessed fall patterns and traffic wear, but noticed settlement within the subgrade material due to improper drainage and water runoff, which assisted in the damage of the playing surface.

PEA GRAVEL

While doing my study, I watched a little girl suddenly fall backwards and onto the pea gravel. She jumped up quick, embarrassed that I had witnessed her falling and then ran away fast holding her back. Pea gravel is cheap but the injuries are not.

Have you played in pea gravel as a kid? How much pea gravel did you empty out of your shoes?

Wood Chips

The wood chip playgrounds that I observed was wet, depleted of material, very abrasive and the smell alone was enough to call “unsafe”.

They had complaints of splinters in hands, wood chip particles in the eyes and stains on the children’s clothes.

Over the years wood chips, bark and other wood materials have served as a replacement for pea gravel. It was much softer to land on than pea gravel.

What people fail to realize is that it is very porous and absorbent and you cannot clean it. It can absorb blood, urine, and vomit and create bacteria that could be unhealthy for children.

Rubber Mulch

Parents and city staffers gathered at the Sea Canyon Park in Dana Point California to discuss the freshly installed rubber mulch that was at their playground. Parents were giving their feedback on the surface and spoke their concerns of it being unsafe for their children. A young neighborhood resident got a puncture wound from the metal bits in the rubber and were demanding it all be removed and a safer surface be installed.

There is a deception when people say that rubber mulch meets the H.I.C testing (head injury criteria). Playgrounds across the globe have I.P.E.M.A. and H.I.C. certifications for their playgrounds at the time of installation. What you don’t consider is when a child jumps off a playset and onto the rubber mulch, the location of the impact will cause the rubber mulch to separate and create a depression in the height of the rubber mulch surface. When another child falls onto that same area thereafter, there is less rubber mulch to protect his/her fall which may cause injury or death if he or she lands on their head.

The maintenance for rubber mulch is outrageous when maintained properly. This means grading, leveling and adding rubber mulch every day to maintain its H.I.C requirements.

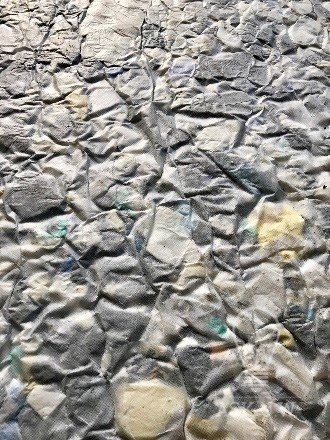

Poured in place rubber (E.P.D.M)

Poured in place rubber (E.P.D.M. ethylene propylene diene monomer) has become very popular over the last decade for playground surfaces. It can be done with many colors and appeasing to the eye, if it is installed correctly. E.P.D.M. surfacing performs differently in extreme climates. If the surface is not maintained and resealed regularly, the surface can become hard and the crumb rubber begins to delaminate. In my years of installing poured in place rubber playground surfaces, I realized how bad the surface can get within a season. Climates that have freeze thaw disintegration can breakdown the urethane binder that gives the rubber surface its cohesion and flexibility. Areas that have high summer temperatures can cause thermal expansion and contraction within the system and cause openings, cracks and separation from edges and equipment. The areas that are susceptible to high traffic begins to fall apart and leave holes up to 4 inches deep.

Synthetic Turf Playgrounds

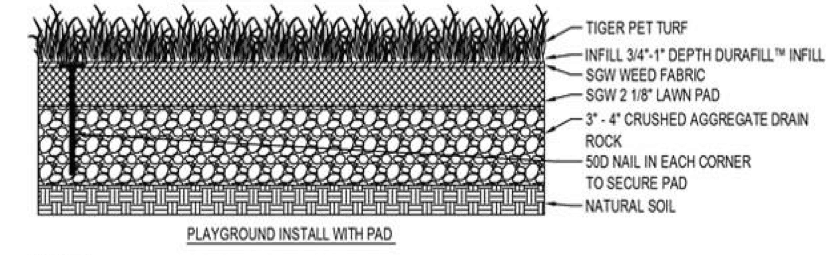

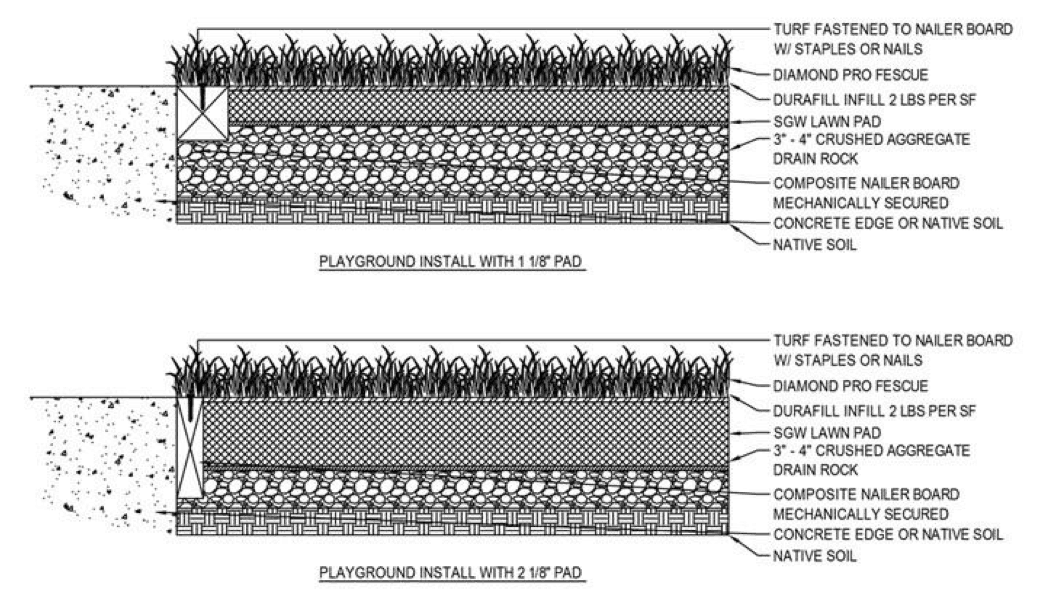

Understanding the complete playground system begins from the ground up. All subgrade materials should be pearmable and retain a minimum of 80% compaction. Creating a stable base will not only assist in the longevity of the system, but will prevent settlement failures that are costly to repair. Using high quality sand and gravel that has good permeation and compactability will withstand heavy down pouring of rain and water run off. Understanding the “wear & tear” areas and placing reinforcement where needed is a vital step for fall height requirements and prevention of premature wearing of the synthetic turf fibers and backing.

Synthetic turf playgrounds surfaces and installations have evolved over the last decade. Underpadding/shock pads that are to meet fall heights (H.I.C. head injury criteria) has improved and now has a longer life span than ever before. The myths about “what style of turf should I use” has been narrowed down to lower pile heights. Taller pile heights under heavy foot traffic lays flat and gets matted over time, depleting the fall height requirments which may cause injury.

SGW Playground installation products & details

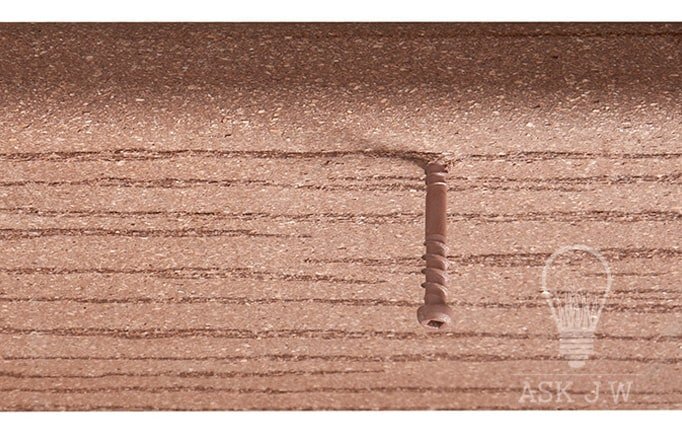

Installing exterior Trex Wood

For the safety of the children, synthetic turf playgrounds should not have any large staples, nails or spikes to secure the synthetic turf. Tex wood is recycled wood and plastic composite made into formed boarding. It comes in many sizes and withstands extreme climates without splitting or splintering. The trex wood is attached to the exterior edge of hardscape. The synthetic turf is then secured on top of the trex wood by using small staples. I recommend pre drilling holes into the trex wood then bolting the trex wood to the hardscape using concrete screws or anchors.

Once the trex wood is in place, grade and compact the imported materials at the elevation that is needed to receive the Underpadding/shock pad. Depending on the thickness of underpadding/shock pad, the finish elevation should be ¼” above the trex wood to account for future settlement. This will allow the synthetic turf to lay flat on the trex wood. Using a air gun staple gun, secure the synthetic turf edge every 4” on center into the trex wood.

If the playground does not have a hardscape border then you will need to concrete the trex wood into place then follw the grading procedures.

Subgrade preparation and grading of imported materials

The existing soils that the playground is to be constructed on must be stable and have permeable qualities. Existing soils that are too soft or have clay like properties must be removed and replaced with quality imported materials. Pre grade existing soils and compact any loose material prior to placing imported sand a gravel.

When the existing sub grade materials are compacted, Place 6 inches of ¾”clean crushed aggregate, compact with a plate compactor to flatten.

Place 1”-2” inches of either decomposed granite, chat or a clean sand over top of the ¾” crushed aggregate. This will be used as a sand cushion over the compacted aggregate. Compact this material with a plate compactor to allow a smooth surface for the next process of placement of Underpadding/shock pad.

Installation of soil stabilizer (optional)

If you have any concerns of improper drainage or unsuitable existing soils, I recommend placing a 200 lb. per square feet soil stabilzer fabric. This will maintain the subrgades stability during extreme flooding and water run off. Secure the soil stabilzer fabric every 2 feet on center in a grid pattern.

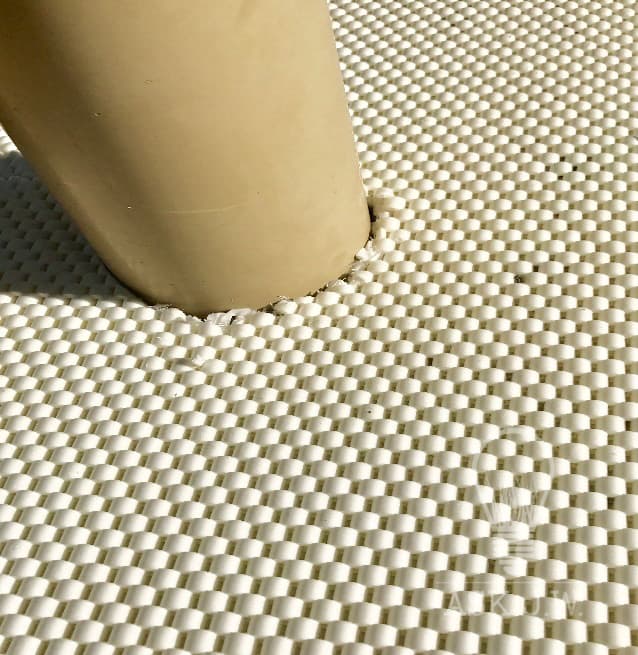

Installation of the underpadding/shock pad

Underpadding/shock pad is to be installed directly under the turf to deliver additional shock absorbency to ensure children’s safety. Made of recycled materials and available in 3/4“, 1 1/8” and 2 1/8” cushions to meet or exceed fall-height or ADA requirements. SGW carries light, medium and high density foam for all playground and sports field applications.

Through rigorous third party testing, Synthetic Grass Warehouse’s top seven TigerTurf products meet the requirements for the American Society for Testing Materials F1292 certification. This testing certifies each of these products achieve the criteria for G-Max (shock) in addition to the Head Injury Criterion score, which measures the impact severity quantifying the risk of head trauma.

The Ultimate Pad is a thinly woven pad (approximately 7/16” thick) that can be placed directly underneath any synthetic grass install to deliver additional shock absorbency. One of the main safety benefits of the Ultimate Pad is that it reduces the GMAX and Head Injury Criterion (HIC) numbers making it the top choice for any playscape. The Ultimate Pad also provides superior drainage that drains both vertically and horizontally up to 80 inches per hour.

Underpadding/Shock pad failures

Over the years I have witnessed failures that has caused playgrounds to be shut down due the safety concerns regarding underpadding issues. Underpadding installed incorrectly can cause the entire project to be removed and replaced. Separation of the underpadding due to thermal contraction and expansion in dry desert climates can break down inferior padding and cause it to shrink, disintegrate and sometimes heaving. Heaving underpadding can cause seam separation in the synthetic turf surface. When the underpadding/shock pad is installed incorrectly the entire playground system will fail.

I recommend placing seam tape and adhesive to all connecting edges of underpadding/shock pad.

Seaming the underpadding sections together will give the entire playground stability and withstand heavy foot traffic without causing the underpadding to settle which is the start of synthetic turf splitting. (notice the settlement of the foam padding in the picture to the left)

Lay out & placement of the Underpadding/Shock pad

I recommend using new SGW infill when the repair is complete and cured.

The fabric side of the underpadding should be face down onto the soil.

This side down.

This side up.

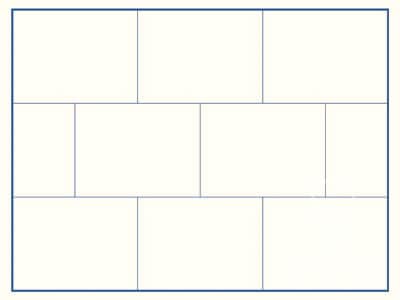

Place the underpadding/shock pad on top of the compacted materials in an offset pattern like the diagram shown above.

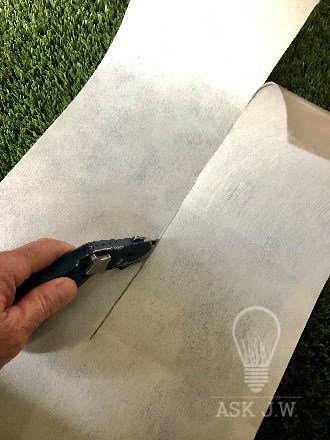

Trimming of the Underpadding/Shock pad

Precisely trim around all playground equipment and edges. It is very impotant that you do not leave any gaps around playground equipment and edges.

Securing the Underpadding/Shock pad

I recommend using seaming tape and adhesive to secure the underpadding/shock pad together. This will prevent the underpadding/shockpad from moving while installing the synthetic turf. It will also give the playground system stability during heavy use. Do not use more than a 6” seaming tape and adhesive. Larger widths of seaming tape and adhesive will lessen the flexibility of the underpadding.

Using a roll of SGW seaming tape, cut strips into 3” to 6” wide, place Superseam Pro adhesive to the underpadding and secure with the seaming tape. You may also find a 6” roll of fiberglass seaming tape at your local hardware store, but make sure it is of SGW quality. Place seaming tape at all seams and glue all sections together as you go so that you can keep the connections tight without having to go back and re-adjust. Seam tape and gluing all underpadding sections together will give the entire underlayment stability as a whole.

Installation of the synthetic turf

DO NOT lay out the synthetic turf where there are seams under heavy foot traffic areas. This would be slides, swing sets, climbing features and play equipment exits. The underpadding/shock pad is flexible, if a seam is placed in these areas it will eventually cause seam seperation. You might have to figure in your costs to have waste to avoid having seams in these areas.

I recommend placing a dense nylon putting green material at all slides, swing sets, climbing features and play equipment exits. This will minimize the damage synthetic turf may receive over the years of heavy foot traffic.

The damage that is in the picture to the right could have been prevented by acknowledging and reinforcing the “wear areas”.

Seaming of synthetic turf playgrounds

Synthetic turf playgrounds should not have any staples, nails or spikes within the playground system. If any staples, nails, or spikes are used, they might come loose over time and cause injury. All seams should be adhered with seam tape and glue. I recommend using SGW fiberglass seaming tape and Superseam Pro adhesive.

It is very important that all edges of the playground system turf be flush with the hardscape to prevent trip hazards.

Placement of infill

I recommend placing a mixture of SGW Crumb Rubber and SGW DURAFILL as the infill for ballast. DURAFILL is the latest technology in infill product for synthetic grass. Animal Urine, blood, vomit and other external elements are not absorbed into SGW Envirofill which eliminates the building of bacterial spores within the infill product. Envirofill does not degrade over time and does not need repeated applications other than having to infill areas where traffic, wind and removal due to “walk off”. Envirofill is environmentally safe and does not contain silica dust, zinc or heavy metals. It is important to place the infill into the fibers slowly so that you do not trap the fibers. Placing excessive infill to fast will not only trap the fibers, but may jeopardize the surfaces fall requirements. Place Envirofill as per synthetic turf manufacturer’s recommendations.

Synthetic turf playground maintenance

Every playground system needs maintenance. When heavy traffic areas start to lay flat or matting occurs, I recommend placing a mixture of Envirofill and crumb rubber to revitalize the playing surface.

Synthetic turf playground repairs

The good thing about synthetic turf repairs is that you don’t have to spend a fortune in materials to make small repairs. I traveled to San Anselmo California to repair a small section of synthetic turf on a playground due to a contractor placing a seam in the middle of the swingset. Children were dragging their feet and pulling the seam apart. I simply cut out the area and replaced it. The repair was simple and less expensive than other playground surface repairs that will not last over time. This is why I recommend placing a dense nylon putting green synthetic turf in all heavy foot traffic areas.

I have installed thousands of square feet of all types of playground surfaces. I also have maintained and repaired them as well. A synthetic turf playground system combining quality materials and installation will outlast any surface on the market. Synthetic turf playground surfaces are my #1 choice.

Stay tuned for next months “Ask J.W.” column

For more information contact J.W. askjw@sgwcorp.com or call 888.846.3598

Other Topics:

About SGW

Learn more about SGW

Certifications

IPEMA, Lead-Free, and CAD Details

Warranties

Our Industry Leading Warranties

Ask an expert

See if we’ve answered your questions

Media

Our tried and true steps for installation

Blog

Learn about our turf in depth

Here to help

Our Commitment

We are committed to providing the best artificial turf products at competitive prices. Our warehouse carries the most advanced synthetic grass products available, engineered to look and feel like real grass. Every turf product is made with high quality materials that are safe for everyone, especially children and pets.

Industry Leaders

SGW San Luis Obispo has always stood out among competitors, offering new products with the latest technology.

Service Oriented

The only thing better than our grass is our customer service. Our staff is committed to providing the best experience possible for our clients.

Quality Driven

At SGW San Luis Obispo we only offer products that maintains a high standard of quality. Backed by up to a 15 year warranty, the best in the industry.