Nailer Boards in Landscape Synthetic Turf

The synthetic turf industry has been so exciting lately with more uses being offered than ever before. Designers, architects, and engineers are acknowledging the fast-growing industry and finding themselves researching proper methods and systems that can be incorporated within their projects. In two decades, securing synthetic turf hasn’t changed much other than the need to do away with embeds (nails, spikes, staples) for securing sections. Securing synthetic turf embeds has been installers choice for years and still is the majority method. Nailer Boards are becoming a favorite among designers, architects, and engineers because the exterior perimeter is equally stable when installed and fastened correctly.

This Month ASK JW will explain what a nailer board is, and its many uses in the synthetic turf Industry.

What is a Nailer Board?

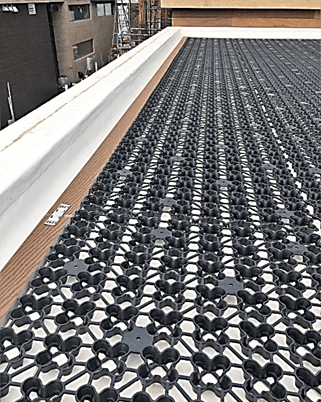

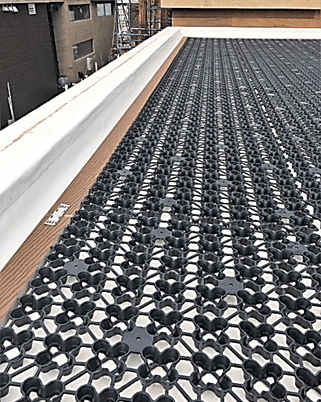

The word “nailer board” is a term that is widely used in the construction industry. A nailer board in synthetic turf is for securing the synthetic turf exterior edge from lifting and movement. Many synthetic turf installations installed today use exterior edging to contain the turfed area. If an outside edge is not created, the edge of the synthetic turf will settle and cause instability and may result in injury.

Decades ago when nailer boards were first introduced to the synthetic turf Industry, pressed and treated lumber was the #1 choice for nailer boards. This material worked great and lasted through warranty periods of the turf, which was only a maximum of 8 years back then. Today, warranty periods are being offered up to 15 years. Treated lumber may last a long time, but eventually, it splits and dries out. The splitting can almost happen immediately due to drilling holes for securing to its hardscape. The times have changed and so have nailer boards and what they are made of. A majority of nailer boards on the market today are made of durable recycled poly/plastic which withstands the test of time. Poly/plastic composites can withstand years of harsh weather and do very well under extreme areas where thermal expansion/contraction is a concern.

What Type and Size Nailer Board Should I Install?

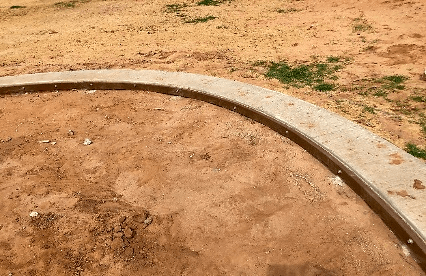

SGW carries all types of nailer board/edging in lengths and thicknesses. 1″ x 4″ x 20′ is the biggest seller and can be cut down to any length. Made in the USA, SGW Polyboard is a remarkable alternative to today’s synthetic turf nailer board/edging products. Polyboard is quickly becoming the preferred product for landscape applications in the home, commercial landscaping, and sporting industries. SGW Polyboard is superior to other lawn edging/nailer board products because of its durability and multiple uses. SGW Polyboard can be bent and curved easily instead of having to cut splices for tight radius and curves. SGW Polyboard can be drilled into without splitting and cut without splintering.

What Tools Will I Need?

- Sgw Polyboard

- Chalkline

- Hammer Drill & Bit

- Sledgehammer

- Embeds (Red Heads,conset)

- Superseam Pro 444

- Staple Gun/plenty of Staples

- Plumbers Torch (if Sharp Curves)

How to Install Nailer Boards for Landscape?

SGW Polyboard is installed to surround the entire area for the anchoring of the turf. As per ADA (American Disabilities Act) Compliance, I recommend placing the nailer board no more than ½ inch below any adjacent solid surfaces where there could be foot traffic or a potential trip hazard.

If the area to be installed is in an area solely by itself, and without any hardscape, curbing, or concrete to secure to, you will need to install the nailer board as you would installing an exterior vertical edging.

When using the exterior edging as a nailer board you must wrap the edge of the turf over the backside of the edging to give stability to the connection. Please note, placing landscape edging as a nailer board is less stable than anchoring to concrete, hardscape or a curbing. When doing so, I recommend securing the edging/nailer board with poly stakes every 18 inches, then secure with metal screws. This will ensure that the exterior edge will not have any movement. Make sure you drive the stakes below the outside edge so that they will not be in your way when wrapping the turf over the edge when stapling. This Installation is like installing other edging products, requiring tools such as shovels, spade, sledgehammer, string, rake, etc.

When placing the nailer board to concrete, hardscape or curbing, I recommend marking the elevation on the hardscape and snapping a chalk line to the proper elevation – this will make it easier for your team to hold 20 feet long sections on the elevation marks.

Once the lines are all marked, have enough manpower to hold the nailer board to the marked line and drill every 18 inches on center and 6 inches from every end – use a hammer drill with a bit that is for the size of the anchor you are using. Have a brush ready to clean the drilled holes of any contaminants. I recommend placing Superseam Pro 444 on the back side of the nailer boards prior to securing, this will assist in the connection due to thermal contraction and expansion and will give longevity to the connection.

If you have sharp bends to make, I recommend using a plumbing torch and heat up the nailer board composite. This will allow it to bend more easily. Make sure it is NOT WOOD!

When the holes are drilled insert the anchor and secure tightly.

Make sure that you DON’T drill the holes too close to the edge of the nailer board – this reduces its longevity and strength.

Once the nailer board is in place and secured, double check all areas that may need extra anchoring. When the nailer board is in place, install the chosen synthetic turf system and staple with an air/electrical staplegun a minimum of 2 inches on center and half an inch from the outside edge (around the entire nailer boards edge). Always do a “Pull Check” to ensure that turf edging is secure.

I have installed thousands of feet of nailer board. I also have repaired them as well. A good nailer board system combining quality materials and installation will last for years.

Ask JW

Stay tuned for next months “Ask J.W.” column

For more Information or if you would like to speak to JW regarding other Turf questions, please feel free to call him at (888) 846-3598 or email askjw@sgwcorp.com

Other Topics:

About SGW

Learn more about SGW

Certifications

IPEMA, Lead-Free, and CAD Details

Warranties

Our Industry Leading Warranties

Ask an expert

See if we’ve answered your questions

Media

Our tried and true steps for installation

Blog

Learn about our turf in depth

Here to help

Our Commitment

We are committed to providing the best artificial turf products at competitive prices. Our warehouse carries the most advanced synthetic grass products available, engineered to look and feel like real grass. Every turf product is made with high quality materials that are safe for everyone, especially children and pets.

Industry Leaders

SGW San Luis Obispo has always stood out among competitors, offering new products with the latest technology.

Service Oriented

The only thing better than our grass is our customer service. Our staff is committed to providing the best experience possible for our clients.

Quality Driven

At SGW San Luis Obispo we only offer products that maintains a high standard of quality. Backed by up to a 15 year warranty, the best in the industry.