“Why is My Turf Wrinkling?… And How Can I Fix It”?

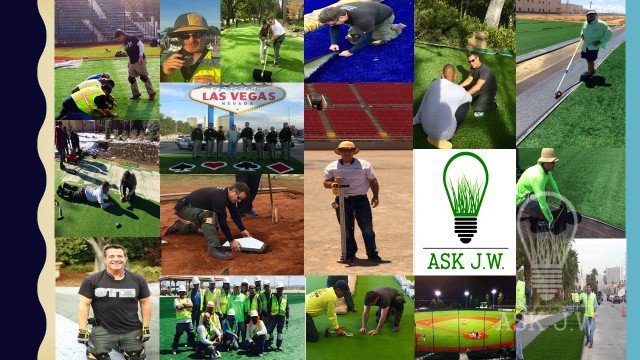

Some of us are experiencing record high temperatures across the nation and the “Ask JW” Hotline has been ringing off the hook with homeowners and contractors asking “Why is my turf wrinkling”?

This month “Ask JW” will teach you why wrinkles appear in synthetic turf, and how to remove them.

The Cause Behind Synthetic Turf Wrinkles

- Improper Ballast / Infill Placement

- Hot temperature changes

- Improper securing of turf

- Poorly manufactured synthetic turf

“Ballast is Very Crucial in Preventing Wrinkling of Your Synthetic Turf”

- “Ballast” is defined as a heavy material used to improve stability and maintain balance and steadiness. In the turf world, the term Ballast is used to “Weigh down the turf, prevent wrinkling and give the entire turf system stability and longevity. Properly placing infill assists the turf fibers in maintaining vertical position.

- “Thermal expansion” is defined as the tendency of matter to change in shape, area and volume in response to a change in temperature through heat transfer.

“Understanding these two concepts will play a major role to successful installations in hot summer months”

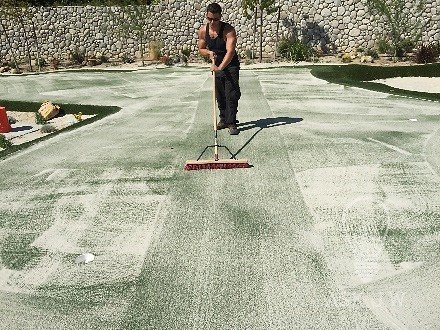

The infill material’s granular size, weight, and how its placed is very important for ballast. I teach installers a close-up view of how to properly infill synthetic turf. I take a small bucket and hand place infill so they can learn how much infill is to placed, the proper depth, and how it feels on the foot, in comparison to synthetic turf that has NO infill. It is critical to understand what it takes to “ballast” each and every synthetic turf product that your company is offering. Educating your team about different infill types, sizes and placement are steps towards preventing wrinkles. Avoid using materials like beach sand, coal slag, dirty silica, fine cement sand. By utilizing the correct infill and amount, you can avoid wrinkling and be proud of your installations

Be mindful of “static electricity” while incorporating your infill. When using a substandard infill and infill size, the installer must aggressively scrub the infill with either a push broom or fibrillating machines to work the infill below the surface. The excessive scrubbing creates static electricity and causes most infill to stick to the fibers and therefore never reaching the base of synthetic turf.

Depending on how long the turf has been down, you can remove wrinkles with the steps listed below. If your turf has been down more than 3 months you may do more damage to the turf by trying to remove them. You may try to ballast or cut out the wrinkle which may rectify the problem.

Prior to removing the wrinkles you must remove the infill so that you may reach the nails/staples. This is very important to successfully remove wrinkles.

“Remember, it is a lot cheaper than removing and replacing the entire project, so be patient”.

Removing wrinkles can be difficult if the synthetic turf has been down for any length of time. When the moisture from the subgrade materials comes in contact with nails or staples that have been placed, Oxidization occurs and creates a rust/bond to the compacted soil. If you are not careful when pulling up nails or staples you will pull fibers from the backing of the turf. If this happens it will cause the surface of the turf to have “Divot” marks and you will end up replacing the entire section.

Removing wrinkles can be difficult if the synthetic turf has been down for any length of time. When the moisture from the subgrade materials comes in contact with nails or staples that have been placed, Oxidization occurs and creates a rust/bond to the compacted soil. If you are not careful when pulling up nails or staples you will pull fibers from the backing of the turf. If this happens it will cause the surface of the turf to have “Divot” marks and you will end up replacing the entire section.

Start at one end and remove the nails/ staples, carefully lifting the turf up and folding it over. You’re your way to the opposite end or till you have reached the end of the wrinkling.

Please notice the wrinkles from the backing due to the synthetic turf not being stretched tight prior to nailing.

Once all the nails/staples are removed, roll the synthetic turf back to its original position. Using a carpet kicker, start at one end and stretch the turf and secure with nails/staples at the same time. Make sure you have plenty of labor to stretch out the wrinkles and secure properly, you don’t want to have to come back and do it again.

When you get to the end, you will need to cut off the excess that you have stretched out. Nail and secure edge.

Here Are Some “Ask JW” Tips to Prevent Wrinkling

Prior to installing the turf, it is important to lay the turf flat for a couple of hours prior to installation. This will allow the turf to conform to the base material and reduce the chances of wrinkles.

**Please remember: If you expose wrinkled synthetic turf to UV sunlight and other harsh environmental conditions for long periods of time, this will cause the synthetic turf to memorize its shape and therefore will be impossible to remove.**

During installation, the turf must be stretched tightly and secured to flatten any wrinkles.

If you have the inner core roll that came with the roll of turf, it makes a good tool to push out all the wrinkles while nailing behind at the same time.

If you are short of nails or staples to secure the turf to the base materials you could experience large wrinkles when it gets hot. Please understand that the backing of the synthetic turf will stretch and cause a crease within the backings gauges. If this crease is not secured and ballast, the crease will have to be cut out and unified by seam tape and glue.

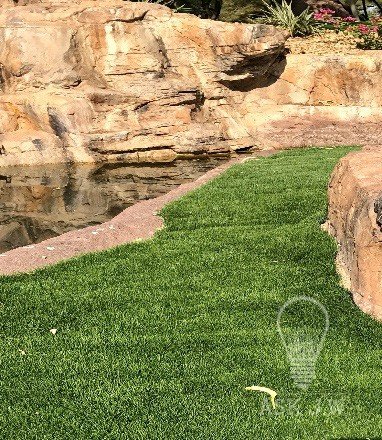

Infill Placement

When your synthetic turf is tightly secured it is important to follow SGW Infill amounts and specifications for each product that you install. Invest in a good drop spreader. Most supply houses carry “Scott Drop Spreaders” which cost approximately $60. A good drop spreader will allow the infill to be evenly distributed.

You may also Order the new “Turf Brush” that is available through SGW. It connects to Scotts Drop Spreaders. It places and brushes the infill into the turf at the same time!

During the infill process, make sure pass with the drop spreader is consistently placing an equal amount of infill onto the surface.

To evenly distribute infill, spread the infill going east-to-west, then north-to-south. Repeat this until all of the calculated infill is placed and has reached the top of the surface where it is visible to the naked eye.

“Prior to starting the installation, I recommend figuring out how many square feet you have? How many pounds of infill does the product require? Then send that amounts to the project and instruct your installation team to not come back to the yard with any full bags” … JW

I recommend working the infill to the bottom of the turf using a curled rake, stiff asphalt broom or a mechanical Power Broom. The tighter the infill to the base of the turf, the better stability the entire system.

Once you have finished your final sweep, about ¼” of turf should be exposed and all of the estimated infill for the square footage that was installed is all gone.

Wrinkles Caused by Workmanship

Sometimes ballast and securing synthetic turf isn’t enough to keep wrinkles from appearing. You may still get wrinkling due to the slope of the areas that you are installing. When your project requires aggressively sloped areas you may have to remove the wrinkles by cutting small strips, and unifying by seam tape and glue.

If you have any questions regarding “Cutting out wrinkles” please email or call my “Ask JW Hotline at (888)-846-3598

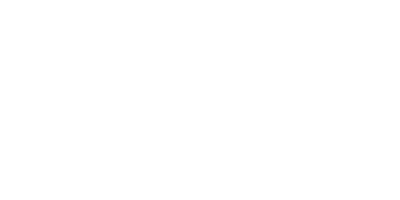

Putting Greens & Ballast

“If you’re Putting Green is wrinkling, please click on the link below and read my column “Avoiding the Putting Green Wrinkling”? This column teaches you in detail how to properly ballast a putting green and create a great playing surface for the avid golfer.

https://syntheticgrasswarehouse.com/avoiding-the-putting-green-wrinkle-effect/

SGW and Quality Control

“Choosing Synthetic Grass Warehouse and all of its quality products is not only advantageous to your pocket book, but your reputation as well. Be careful choosing inferior products when it comes to the Synthetic Turf Industry”.

“Ask JW”

For more information regarding Wrinkling, please contact J.W at 888.846.3598

Other Topics:

About SGW

Learn more about SGW

Certifications

IPEMA, Lead-Free, and CAD Details

Warranties

Our Industry Leading Warranties

Ask an expert

See if we’ve answered your questions

Media

Our tried and true steps for installation

Blog

Learn about our turf in depth

Here to help

Our Commitment

We are committed to providing the best artificial turf products at competitive prices. Our warehouse carries the most advanced synthetic grass products available, engineered to look and feel like real grass. Every turf product is made with high quality materials that are safe for everyone, especially children and pets.

Industry Leaders

SGW San Luis Obispo has always stood out among competitors, offering new products with the latest technology.

Service Oriented

The only thing better than our grass is our customer service. Our staff is committed to providing the best experience possible for our clients.

Quality Driven

At SGW San Luis Obispo we only offer products that maintains a high standard of quality. Backed by up to a 15 year warranty, the best in the industry.