Synthetic turf putting greens are created to simulate realistic play of a natural golf course green. Natural bent grass putting green surfaces are dense, tight, and need continuous maintenance to achieve smoothness and Stimpmeter speeds. Owners of synthetic turf putting greens have this notion that since the surface is synthetic, there will be little to no maintenance. This is not true. Seasonal maintenance is crucial for a synthetic turf putting green. The synthetic fibers of the putting green’s surface never stays the same as the first day you place it. Continuous foot traffic alone can cause dips and valleys where repetitive putts are made. Fibers flip up due to friction and dragging of the feet or shoes. Areas around the cups start to become uneven and slow. When issues like these arise, you will need to inspect the infill depths and roll the entire surface. This month, Ask JW will explain the importance of rolling putting greens during the initial installation and after, as necessary seasonal maintenance.

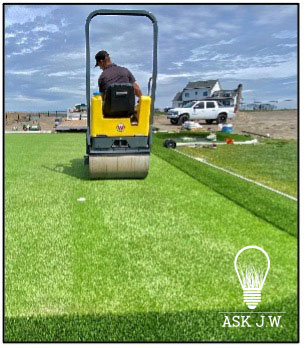

Infill placement at proper heights in combination with “rolling” is the most important ingredient for perfecting putting green surfaces. Most installers are unaware of how rolling creates a smooth surface that evens out imperfections for play of the golf ball. Rolling after infill placement is needed for every putting green’s surface.

Infill & Foot Weight

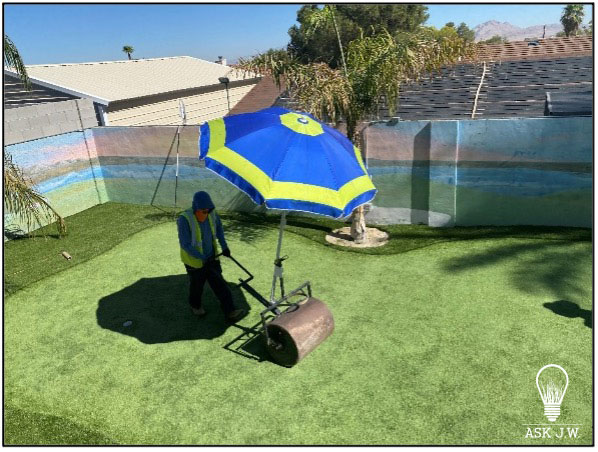

The images above show how foot traffic can cause depressions in the turf’s surface.

Compression

[kəmˈpreSHən]

NOUN 1. the action of compressing or being compressed.

In my previous Perfecting Putting Green Surfaces 3-part series, I explain how weight causes fiber distortion. When the surface fibers depress, it causes dips, ridges, and/or bumps depending on how the golf ball reacts at point of contact with the uneven surface. When the putting green surface is infilled to the highest level, cut, then rolled, it will prevent this from happening.

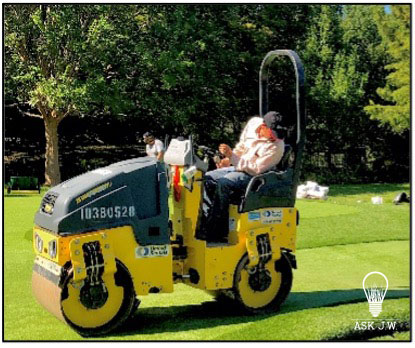

Compression Rolling

The size of the putting green will determine the size of the roller that will be needed. You can purchase a sod water roller from your nearest landscape supply house, or many rental places have them for rent. Make sure the roller is in good condition and does not have any gouges on the outside surface. This damage will cause issues with the surface’s end result. If your putting green is large, you may want to rent a larger piece of equipment so that you aren’t rolling for days.

Temperature

Temperature can make or break a good rolling. If you are trying to roll a putting green in freezing temperatures, it will take longer for the fibers to depress to the infill. Remember that the fibers resemble plastic, so when they are hot, they are more flexible and able to be manipulated. If you have questions on how to roll in the cold without spending days on it, give me a shout.

I recommend pressure rolling after the infill is placed at the highest elevation, cut even, then inspected. Inspecting the surface prior to rolling is important. When you ignore areas of infill that may be left too high, you will have to infill, cut, and roll all over again. You cannot just cut an area/patch where the infill was higher than the rest. You will need to feather out the areas or re-cut the entire putting green. This will allow the fibers to be pressed down to the infill height and create a smooth surface for the ball to roll on.

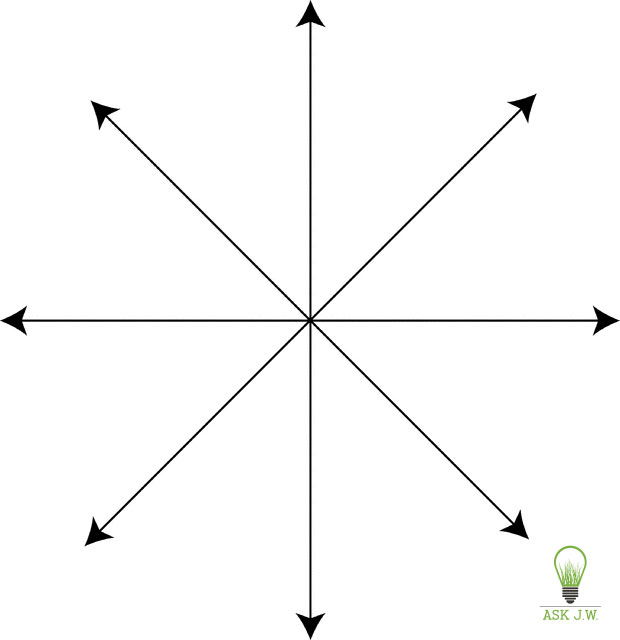

During the rolling process, roll in the directions shown in the upper left image. I train field installers to look at it as numbers on a clock. Go 12 to 6, 3 to 9, 2 to 8, 10 to 4, etc. This is important to acknowledge. If you think you can get by rolling only east to west and north to south, your client will be calling you, and it won’t be for lunch. This equal rolling provides compression that will create a smooth, even surface which will maintain stimp speeds.

*** DO NOT ROLL EXTERIOR FRINGE OR CONNECTING LANDSCAPE TURF, FOR THIS MAY DAMAGE THE FIBERS AND/OR CAUSE MATTING***

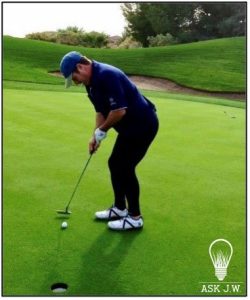

Inspection Putts

Prior to putting the roller away, it is best to do inspection putts. I always recommend having a putter and golf balls on hand when you are building putting greens. A couple golf lessons would help as well. This will allow you to putt from the same direction you have rolled in order to inspect any uneven areas.

For more information regarding rolling putting green surfaces, or to schedule a training, please contact J.W. at 888.846.3598 or email AskJW@SGWcorp.com

Suggestions for the use of ASK JW installation techniques are solely at the end users’ discretion; however, the user should determine suitability for the intended use by his/her own evaluation. Because the use of the materials is beyond our control, neither ASK JW nor SGW shall be liable for the outcome of any use of said materials including any injury, loss, or damage, direct or consequential, arising out of the use or inability to use these techniques and products.

Other Topics:

About SGW

Learn more about SGW

Certifications

IPEMA, Lead-Free, and CAD Details

Warranties

Our Industry Leading Warranties

Ask an expert

See if we’ve answered your questions

Media

Our tried and true steps for installation

Blog

Learn about our turf in depth

Here to help

Our Commitment

We are committed to providing the best artificial turf products at competitive prices. Our warehouse carries the most advanced synthetic grass products available, engineered to look and feel like real grass. Every turf product is made with high quality materials that are safe for everyone, especially children and pets.

Industry Leaders

SGW San Luis Obispo has always stood out among competitors, offering new products with the latest technology.

Service Oriented

The only thing better than our grass is our customer service. Our staff is committed to providing the best experience possible for our clients.

Quality Driven

At SGW San Luis Obispo we only offer products that maintains a high standard of quality. Backed by up to a 15 year warranty, the best in the industry.