Throughout my travels, teachings, and seminars, I have spoken to several contractors regarding their input on synthetic turf waste and where they place its financial burden. After being looked at like I had a third eye, I was amazed to find that the majority were unaware of “Waste Factor” and never figured it in as a profit, loss, or anything for that matter.

This month, ASK JW will talk about layout, waste, and the financial burdens synthetic turf waste causes and what to look for when estimating projects.

“To be a successful synthetic turf contractor, you must educate your entire workforce about Layout & Waste. It is a team effort. To make money you also have to save money. Preventing waste in synthetic turf is crucial in being profitable.

Financial Burden

If you are wanting to make a career in synthetic turf installation, then you may want to pay very close attention to waste and the burden it may place upon your profits.

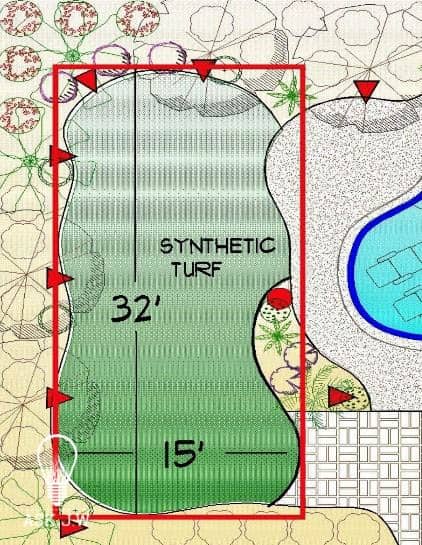

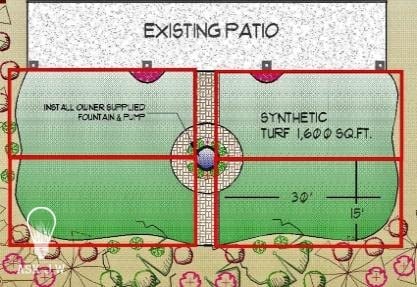

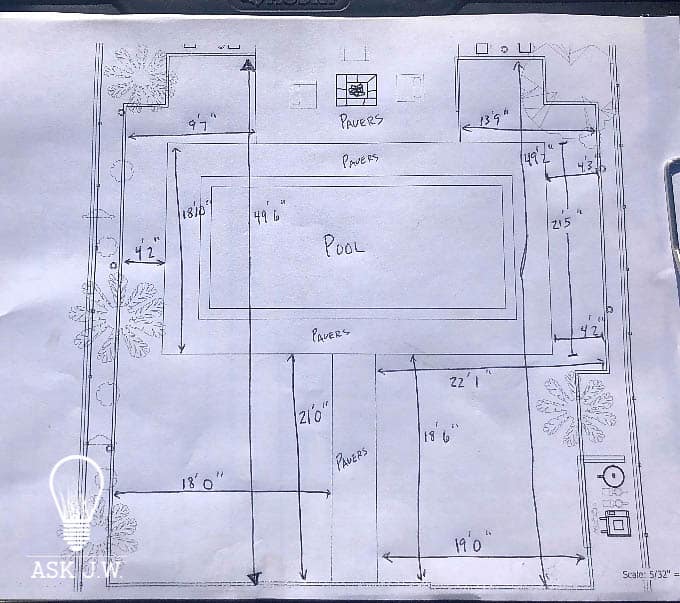

It all begins with estimating. If you and your sales team are new to the synthetic turf industry you may want to brush up on geometry. Geometry and synthetic turf go hand and hand. When sections of turf are cut in a square or rectangle then placed in an area that is rounded, or circular, there will be waste. When you cut the extended waste off you will witness the money that will be thrown in the trash. I recommend using a push cutter (loop and pile cutter), and cut large sections of waste and use them for smaller installations.

Now comes the time where your sales team measures the area to be installed… figures the waste, but doesn’t know how to absorb the cost. It’s easy. “Someone has to pay for it”.

I suggest having the client be a part of the decision making when it comes to waste. Have a diagram of the clients install and show where and how much waste will occur due to their size and geometrical shape. Synthetic turf waste does not require grading, compacting, or installation. It is merely cut off and never used. I recommend having the client pay for the waste.

If the waste is very minimal and your sales team is selling a good and fair price, then you may absorb the waste, just as long as is not dipping into your profits.

Ordering & Waste

A majority of synthetic turf is manufactured at 12 feet and 15 feet widths and the lengths can be as long as 100+ feet. Your sales team will need to understand field layout and measuring, and include waste into their budgets and ordering.

Communication throughout your organization is crucial for saving and making money in synthetic turf. I have witnessed companies sell an install based upon its total square footage and not the exact roll cuts. Then its purchasing department was left blind figuring how to order it. The purchasing department then ordered the turf based upon a 15 foot roll size. When the rolls were delivered, they didn’t fit the layout. They ended up having multiple seams just to make it work, and sections were going in the wrong direction. Being knowledgeable when it comes to layout is not only for waste and saving money but for avoiding seams as well. We all know that bad seams happen. Why have seams in your install due to miscalculating the layout?

Estimating Tools

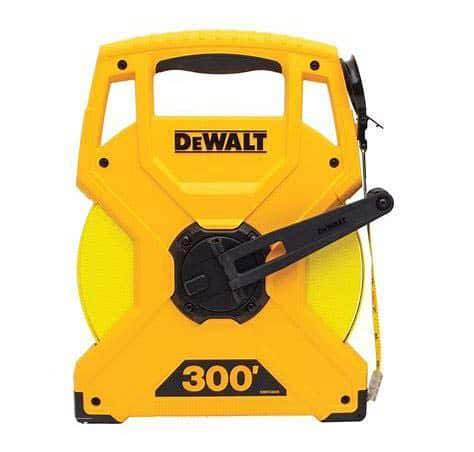

Having the correct measuring tools is a must when estimating synthetic turf. I recommend using a 35-ft tape measure and a 100-ft flexible measuring tape measure. The 35 ft tape measure will allow you to measure 15 roll feet increments, two sections at one time. The 100 ft flexible tape measure allows you to lay the tape on exterior curves and radial measurements for more accuracy. If you are going to use a measuring wheel, I recommend double-checking the wheel and its reset button to ensure you don’t mess up overlapping measurements.

Waste Factor

I recommend figuring a minimum of 10% waste factor for synthetic turf installations. You may need to figure more or less depending on your project. If your project is designed with a round or radial design, your waste factor may increase. Sometimes those nice curvature designs can be costly in material waste. Adding a few extra feet doesn’t constitute making up for all of the waste that may occur on each side of the project. Every project is different than the next and your waste factors will fluctuate.

If you are special ordering any turf that is hard to come by or may take longer to get, I suggest you order plenty to cover waste, mistakes, and future repairs. Dye lots vary from batch to batch and the colors may not match.

Geometry & Layout

Placing hard to move rectangle or square sections of synthetic turf and placing them in and around objects can be challenging. In order for you to be successful at synthetic turf installations, you must be good at geometry – understanding geometry and how sections are laid can be very tricky. Synthetic turf is manufactured in rolls similar to carpet. A majority of synthetic turf that is manufactured today is manufactured in 12 ft and 15 ft widths and the lengths are up to 250 ft long. Landscape turf is usually ordered and cut to the size the contractor chooses. Many times a full roll is purchased and the cuts will be made in the field. When these cuts are made, usually there is extra material that is figured to allow for the turf to overlap the edges, hardscape, and integrating seams. This extra waste is used to grab and then cut to shape. When the edges are cut, this waste is either saved for future projects or too small to save and is disposed of as trash.

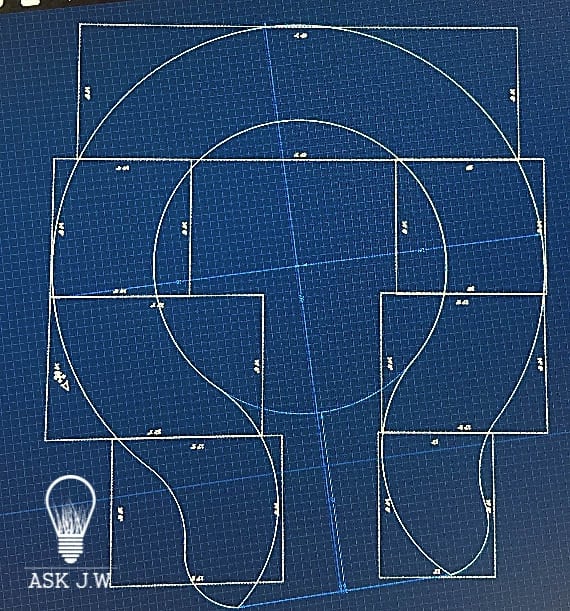

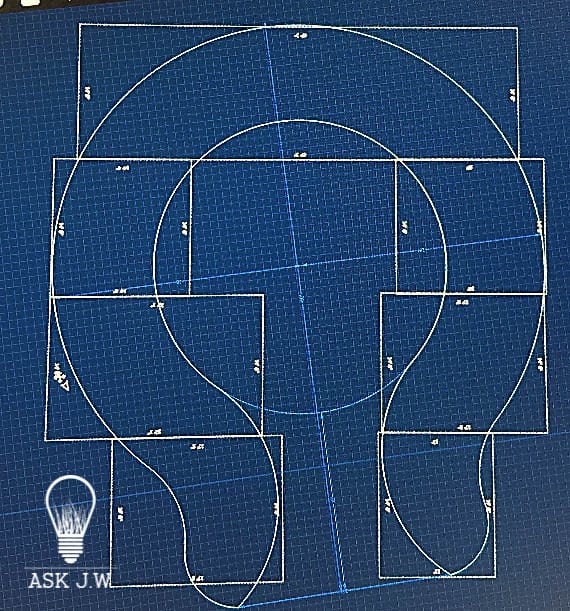

When estimating synthetic turf you must create a drawing, plan or schematic of the area to be installed. If the area is not square you will have to create imaginary lines that will represent the sections of synthetic turf you are planning to lay. I recommend running string lines that will represent the exterior edges of the turf and paint out these areas with upside down marking paint. When you establish the exterior edges and dimensions of the area, write them on your drawing or plan. I recommend ordering enough turf so that you don’t come up short and have unwanted seams.

Layout, Waste & Placement of Seams

Many installers feel they can save money by choosing multiple seams over waste – this is an unacceptable method. Clients are not expecting multiple seams in their installation. Clients expect all of the synthetic turf to be unified as one.

Layout, Waste & Putting Greens

Putting greens are far from being square or rectangle. In fact, you will probably never see sharp edges on the exterior design of a putting green. Just like landscape turf, putting green materials come on rolls of 12 ft and 15 ft widths. Depending on radius and curves, putting greens can have an extensive amount of waste. I recommend having a drawing prior to installing and then marking the entire putting on the surface including the fringe.

When the putting fringe is marked out, take string line and layout where the pre-cut sections will be laid to cover these areas. Immediately you will witness the waste. In order to wrap the fringe material around the entire putting green, you will witness that you will need to purchase large enough sections so that you can minimize seams.

Layout, Waste & Fiber Direction

Putting green fringe that is put together with small pieces creates more time, labor and lots of seams. The fringe is for the golfer to chip off of and when constant foot traffic plays on the fringe, the seams may start to show like parted hair. Not only will it cause you more money in the long run, but if the pieces are not laid in the same direction, you will see different shades of color due to the grain not being aligned. In your layout, never place a seam in the middle of a putting green cup. I recommend not taking the chance and use larger sections and place the burden of cost to the one who will be enjoying the putting green the most… the client.

Layout, Waste & Grass/Sand Traps

Layout and fiber direction are important factors when placing turf in and around grass/sand traps. In order for you to be successful at installing grass/sand traps, you will need to figure extra material to cover over-lapping, seam integration and have enough to cover the existing fringe.

Layout, Waste & Playgrounds

When figuring lay-out for synthetic turf please keep in mind that protecting waste may not protect the longevity of the turf due to wear and tear. Playgrounds can take a beating. If you place seams where heavy foot traffic and play will occur, you will have constant repairs to make. Make sure you spend the money on waste than having to come back and make repairs.

Layout, Waste & Trampolines

When estimating turf around trampolines, you will need to figure placing the turf over the trampoline and cut out the waste. This will give the area stability and minimize seams. If done correctly you will have two large pieces of waste from the middle of the trampoline that looks like the image above to the right.

Layout, Waste & Turf Ribbons

When you are faced with placing synthetic turf in between ribbons or borders, you will definitely have waste. I never recommend placing small strips, pieces, or sections which creates seams. When placing synthetic turf ribbons (like the ones in the image above) I recommend placing large sections then cutting out the hardscape. This will prevent installing excessive seams and unify the entire installation for longevity. It requires a lot of waste and the cost must be explained to the client, or you will lose the project to someone that will hack it up.

Layout, Waste & Contouring

Many synthetic turf contractors are not aware that contouring the subgrade may throw off measurements. I hear stories of contractors having drawings, sketches, and plans for the area before it was installed and didn’t understand why they were coming up short. It didn’t fit the area because their men placed massive mounds in the project which caused certain sections being short of the hardscape and they had to piece it in.

Layout, Waste & Commercial Projects

When estimating large commercial projects, I recommend creating a layout and a numbering system for all sections that will be placed (above center image). Cutting large waste may be used in other places if it is planned correctly. Large installations can make or break your company. Always pre-plan all layouts, measurements, fiber direction, and egress areas.

When you have turf that is high in face weight, the dreaded mohawk may show up. In this case, you will need to integrate the seam. When integrating seams you will need to cut into the edge to create whatever integration you are choosing. The Superseam tool creates only 5 inches of waste for the entire run. When estimating the project you will need to know where your seams are going to land and figure what is needed for overlapping. This means you will need to figure enough waste to run the sections past your exterior edge and enough for any seam integration that you may need.

I get asked a lot of how I became so fast at laying and placing synthetic turf. One important tip? Always have enough manpower to move around synthetic turf and understand the method of folding turf.

Working with synthetic turf is like working with napkins and towels. They can be folded into many shapes on how you want them to be. Even though synthetic turf is much harder to handle than napkins or towels, the folding methods and techniques are actually the same. When you arrive at a project, you must have in mind how you are going to wrap turf around trees, buildings, walls etc. With the understanding of the folding method and how easy it can be, it will make your installs much easier and faster.

Stay tuned for next month’s “Ask J.W.” Column!!!

For more information regarding layout, measurements, and waste, please contact J.W. askjw@sgwcorp.com or call 888.846.3598

Other Topics:

About SGW

Learn more about SGW

Certifications

IPEMA, Lead-Free, and CAD Details

Warranties

Our Industry Leading Warranties

Ask an expert

See if we’ve answered your questions

Media

Our tried and true steps for installation

Blog

Learn about our turf in depth

Here to help

Our Commitment

We are committed to providing the best artificial turf products at competitive prices. Our warehouse carries the most advanced synthetic grass products available, engineered to look and feel like real grass. Every turf product is made with high quality materials that are safe for everyone, especially children and pets.

Industry Leaders

SGW San Luis Obispo has always stood out among competitors, offering new products with the latest technology.

Service Oriented

The only thing better than our grass is our customer service. Our staff is committed to providing the best experience possible for our clients.

Quality Driven

At SGW San Luis Obispo we only offer products that maintains a high standard of quality. Backed by up to a 15 year warranty, the best in the industry.