For decades the most recognized problem in the synthetic turf Industry has always been visible seams. Installers are either uneducated, scared, or too lazy to use seam tape and glue to unify their seams. Why is that? For some, it is convenience. For others, it’s not understanding how easy the process is. Creating seams that are undetectable requires skill, patience and the proper adhesive to ensure longevity. Superseam Adhesives will allow you to sleep at night knowing the seams you installed yesterday will not come apart tomorrow.

This month ASK JW will dive deep into unifying two sections of synthetic turf with Superseam Adhesives, and teach the basic methods which will allow your installation of seams to be effortless.

“Understanding the installation of Seam Tape and Glue when unifying two sections of synthetic turf together is what sets apart the beginners from the professional” … JW

What is Superseam Adhesives Made Out of?

Superseam Adhesives are moisture cured urethanes made up of a blend of the strongest polyurethanes or polyurethane/prepolymer. Superseam Adhesives work by means of chemical and mechanical bond rather than just a mechanical bond. They chemically “attach” themselves to the surface as well as “grabbing” and “Locking” onto the substrate. Superseam Adhesives mechanical properties include elongation, compressibility, tensile strength, elasticity, tear resistance and fatigue resistance. When unifying two sections of synthetic turf, the seam could move considerably, requiring that the adhesive to expand and contract significantly without losing adhesion from the seam tape and backing of the turf. Temperature, rate of temperature change and how the adhesive was applied will influence the results.

Superseam Adhesives has the ability to withstand harshest weather conditions with great longevity. Superseam Adhesives can be used indoors or outdoors with proper ventilation. Superseam Adhesives have many uses in the synthetic turf and carpet industry including “Glue Down” on exterior surfaces such as concrete, pavers or clean asphalt.

- Superseam Adhesives are manufactured in the U.S.A with no pigments.

- Excellent water resistance.

- Flexible

- No foaming through seams at high temperatures.

- Excellent Freeze Thaw Strength and longevity

- User friendly and workable cure times.

- Great adhesion and superior strength in heavy traffic areas.

- Superseam Pro Adhesive can be used in Synthetic Turf Glue Box applications.

- Bonds to most surfaces

Superseam Adhesives Quality & Strength

Superseam adhesives have been through vigorous performance testing, including the “Underwater Peel Test”. This is crucial to the longevity of the adhesive. Many adhesives that are being used as synthetic turf are failing. When applied correctly, the adhesive must outlast or equally perform the warranty of the synthetic turf.

REMEMBER; the adhesive lays beneath the turf backing, exposed to harsh weather conditions, including excessive moisture & thermal contraction/expansion.

Installing seams with weak or inferior adhesives can fail within months.

Where most turf adhesives blister and foam, Superseam Adhesives trowel out smoothly.

Superseam Adhesives can withstand extreme temperatures and don’t have to be cooled with ice.

Superseam Adhesives have a long track record of longevity and doesn’t dry out like most adhesives that are placed on top of underlying soils.

Superseam Adhesives are excellent for making repairs that you can rely on.

Las Vegas Strip Medians

Still today, the seams on the Las Vegas Strip Medians remain just the same it was installed decades ago, thanks to Superseam Pro 444.

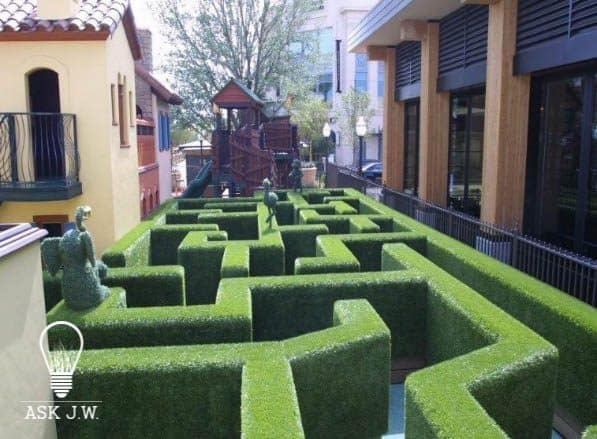

Superseam Adhesives & Sports Surfaces

Superseam Adhesives are relied upon to keep seams bonded under extreme wear & tear. Seam ruptures are a common in the synthetic turf and that’s why Superseam Adhesives dominate the Industry for strength and longevity.

Billy Herbert Baseball Stadium

McGregor & Fort Bliss Army Base Practice Fields

Professional Batting Cages – Placed on Concrete with Superseam Pro 444

Crossfit Gyms

Specialty Projects

Rooftop Glue Downs

Now that we know understand the strength and uses of Superseam Adhesives, let’s dive into how to make the best of your seaming applications.

Let’s begin*

Manipulation

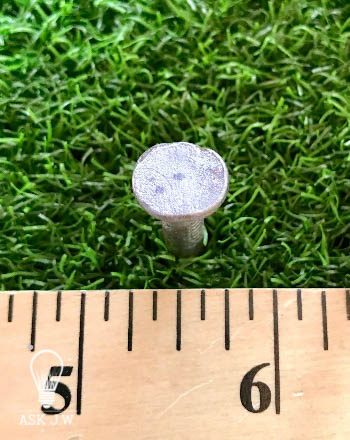

Manipulation of fibers is the main culprit for visible seams. Placing embeds (nails/staples) down in and between the turfs fibers will cause manipulation and will cause the seam to be visible. It is merely impossible not to trap fibers when installing nails or staples.

Manipulation is Created in Various Forms

- Pulling on the fibers at the seam line

- Clearing fibers as you place the embeds (nails/staples)

- Smashing the fibers as you place embeds (nails/staples)

- Hammering too deep into the base of the backing causing divots in the underlying compacted soil

- Trapping the fibers with the nail head while placing into turf.

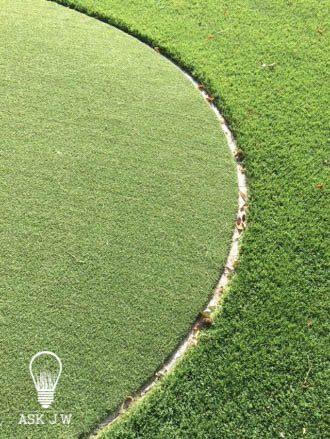

Nails or staples that are placed at the seam will manipulate the fibers and cause the seam to be noticeable. As you can see the above pictures show how embeds (nails/staples) can cause havoc on seams. Most nails heads are too big and cause the fibers to be manipulated and cause the seam to be visible, especially after the infill is placed. This is why I recommend using the seam tape and glue method.

“Staples Trap Turf Fibers”

Using staples in hard, rocky areas can cause the staple to bend outwards and cause the seam to separate. (Notice the pictures above of staple width after being placed in these type of conditions).

Staples have two spikes on the staple that you must clear fibers from. Staples also have a crown that can trap fibers if not carefully placed.

When installing staples you also must constantly inspect the seam width during the seaming process. This will ensure that the staple does not pull apart the seam past its required gauge width if it is subjectable to hitting rocks, or hard soils.

Fail to Plan…Plan to Fail

To have a successful seam installation, preparation is the key.

- Think safety

- Check the weather and make sure there isn’t any future rain in the forecast.

- Have all materials on the jobsite and ready to use.

- Store all Superseam Adhesives in a cool dry place until ready to use.

- Have plenty of help when installing seams.

- Have the proper trowels to apply the adhesive.

- Have a “Spill Plan”. Murphy’s Law … It will happen.

- Double & Triple check the seam prior to placing adhesive, most seams will move with the changes in temperature. I have had many times that the seam had to be kicked together due to the extreme heat that rushed upon us, while in the gluing process.

- Get all the compression bags lined up tight with one another down the seam line.

- Place all adhesive pails and buckets on a protective tarp or cut a 2’x2’ piece of turf to place the adhesive on while not using.

- ALWAYS CLOSE AND COVER THE ADHESIVE CONTAINER. If there is any moisture or humidity it will cause a layer of adhesive to cure inside the container.

- Place the adhesive on the seaming tape as quickly as possible. The faster you get the two sections of turf down on top of the adhesive the better strength you will achieve.

- Knock down any excessive glue that was troweled more than the required depth. Anything over a 1/8 inch in thickness may cause issues.

- ALWAYS do a bag check every ten minutes to ensure there isn’t excess glue seeping up through the seam or drainage holes. This means pulling up chosen bags to check seeping.

Teamwork

“If you are installing seams, make sure you have enough man power per foot. If you short cut on labor, your seams will come up short on quality”

JW

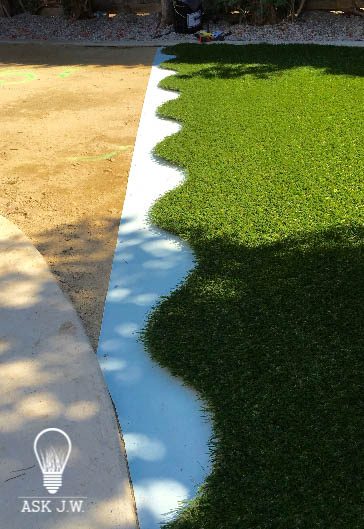

When I physically teach turf crews the JW seaming method, it blows their mind how fast and perfect the seams turn out. Any group of installers can become experts at seaming if they create a team, tasks and act of execution. You must have plenty of help for the length of the seam. This allows controllability. The picture at the upper left shows 6 men installing a putting green seam. As you can see they have full control of the two sections. With enough men per foot you can:

- prevent the edge of the turf from dropping/flipping onto the troweled adhesive

- place the seam to its manufactured gauge width

- double check seam width,

- pull fibers upright

- bag for compression

It is important to secure the placement of the seaming tape directly in the middle of the two connecting sections of turf. This gives equal adhesion for both sections. Place the seaming tape tightly against the soil with no wrinkles and any hardscape areas to prevent lifting or foot drag.

When securing the seaming tape with embeds (nails/staples) make sure you don’t over drive the embed into the seaming tape. Excessive adhesive will rest in the depression of nail head and may cause issues with seeping through seams or drainage holes.

Placing synthetic turf seam tape improperly is another reason why seams fail. SGW Synthetic Turf Seaming tape is manufactured with a plastic film on one side. This film side MUST BE FACED DOWN!!! Against the compacted underlying subgrade materials. This plastic film protects the seam and its adhesive from ground moisture. If the plastic film side is placed up and adhered to the backing of the synthetic turf the seam will pull apart and will have to be reinstalled properly.

Construction adhesives are NOT made for synthetic turf seams

It is important to secure the placement of the seaming tape directly in the middle of the two connecting sections of turf. This gives equal adhesion for both sections. Place the seaming tape tightly against the soil with no wrinkles and any hardscape areas to prevent lifting or foot drag.

When securing the seaming tape with embeds (nails/staples) make sure you don’t over drive the embed into the seaming tape. Excessive adhesive will rest in the depression of nail head and may cause issues with seeping through seams or drainage holes.

Placing synthetic turf seam tape improperly is another reason why seams fail. SGW Synthetic Turf Seaming tape is manufactured with a plastic film on one side. This film side MUST BE FACED DOWN!!! Against the compacted underlying subgrade materials. This plastic film protects the seam and its adhesive from ground moisture. If the plastic film side is placed up and adhered to the backing of the synthetic turf the seam will pull apart and will have to be reinstalled properly.

Roofing Tape is NOT made for synthetic turf

Many contractors are using this economical, fast roofing repair tape as a synthetic turf seaming tape. Roofing Repair Tape is not manufactured or tested as a Synthetic Turf seam tape. It does not have the ability to successfully cohere two sections of synthetic turf together. The pictures below show that the roofing repair tape only touches the exterior of the gauges and does not reach up and between the gauges to the backing. I personally have witnessed hundreds of seam failures that was seamed together with roofing repair tape. You can easily pull the seam from the tape months after the roofing tape has been placed. I recommend to never use this as synthetic turf seam tape.

CORRECT APPLICATION TOOLS ARE A MUST !!!

In my decades of being in this Industry I have witnessed some crazy tools being used to apply turf adhesives. I have seen Drywall spatulas, cardboard, turf scraps, folded seaming tape, and yes, a paper cup. Using the improper tool to apply the adhesive will create the seam to fail.

All adhesives on the market today have their “width of material” written in their specifications of how much to be applied to the surface. Most turf contractors never read labels on their products… TOO MUCH IS TOO MUCH!

Too much Seam Adhesive can affect the seam and its fibers integrity. Placing the wrong adhesive especially in the hot summer months can cause the adhesive to expand, foam and seep up through the seam line and stick to the fibers making the seam visible.

Using moisture cure adhesives that creates excess foaming properties can also a cause seam failures, I recommend NOT using these. Excess foaming causes the seam to lift, creating noticeable seams. I recommend using Superseam Pro adhesive which does not foam and can be used in extreme weather conditions.

Ask JW Tips & Tricks

Controlling how much adhesive you want to apply is critical. Using a mortar bag or cutting the corner off of a contractor trash bag works great like applying pastry on a cake. Just carefully pour the adhesive into the bag, then cut off the end, fold to close and un-fold to open. Then start squeezing it out! This works great for seaming putting green fringe to putting green turf.

When the adhesive is applied to its required thickness, knock down any excessive glue lines and globs and level them out. It prevents adhesive from seeping up through the seam and drainage holes.

The Importance of Compression

When installing synthetic turf seams you must create compression after placing the adhesive on the seaming tape.

- Adhesive Seam Compression: pressure that is applied to seaming area of two sections of synthetic turf onto adhesive glue and seaming tape

When was the last time you had broken a dish, glass or object that needed to be glued back together?

Did you hold it together while the glue dried?

Most objects or materials that are to be unified by adhesives need some type of compression while in its curing stage. Compression allows the adhesive to be forced into voids and capillaries within its adhesive zone and ensures the bonding performance.

Don’t chance seam failure, keep compression on your seams until the adhesives are cured.

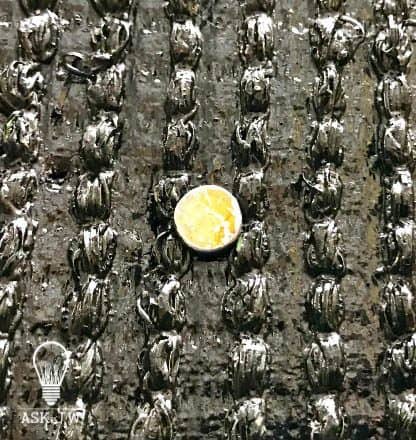

The pictures above shows Superseam Adhesives applied at the correct depth and proper compression applied.

The center picture shows a close up and cut view of how compression forced the adhesive up and through the stitch rows, gauges and backing. Compression prevents voids and air pockets from occurring between the seaming tape to the backing of the turf.

When your seam integration is complete I recommend placing infill bags (no heavier than 50 pounds) on top of the center of the seam after gluing for approximately 30 minutes. This will allow for proper compression to allow adhesive/glue to reach the entire backing between the gauges/stitch rows.

If the weight on the seam is too heavy, the adhesive will forced up through the seam and drainage holes.

Ask JW Tips & Tricks

If you want to perfect hiding your seams, this is a trick I created to ensure they will be invisable. This technique manipulates the fibers vertical to create memory of their position and prevent excess adhesive reaching the fibers.

- When placing the first bag, place it vertical and lay over a team members hands.

- assist in flattenening the bag to create even compression.

- The team member will pull his hands from underneath the bag pulling(clawing) the turf fibers vertically.

- repeat these steps till you have reached the end of the seam.

“ Below is a video that will assist you in this seam bagging technique… Try it, you will be amazed”…. JW

Continuous Inspection

Continuous Inspections of the seam throughout the seaming process is very important, especially in hot summer installations. The heat may cause the synthetic turf to expand and contract which will cause the turf to move. After the Adhesive/Glue is placed, inspecting the seam while connecting the both sections together will allow the installer to make adjustments to ensure the seam is tightly seamed together. When applying adhesive on days with higher temperatures, always inspect the installed seam throughout the curing process. This will prevent the adhesive to bubble/seep up through the seam and drainage holes. Just because your seam is glued and you have other tasks to complete the entire installation does not mean you avoid final inspection of the seam.

Allow Superseam Adhesives to cure a minimum of 24 hours before putting into service.

Always remember to always install turf seams early in the morning or late afternoon to prevent yarn shrinkage. The heat of the day will not only cause the seam to expand and contract, it will also cause the synthetic turf glue to set up too quickly or bubble/seep through the seam. You may learn more about yarn shrinkage on the SGW website.

I hope you are enjoying the columns that I write. As you can see I have an extreme passion for synthetic turf. Thank you for your calls and emails seeking advice on your installation issues. I enjoy creating new relationships.

JW

For more information regarding the ease of Superseam Adhesives, please contact J.W at 888.846.3598

Other Topics:

About SGW

Learn more about SGW

Certifications

IPEMA, Lead-Free, and CAD Details

Warranties

Our Industry Leading Warranties

Ask an expert

See if we’ve answered your questions

Media

Our tried and true steps for installation

Blog

Learn about our turf in depth

Here to help

Our Commitment

We are committed to providing the best artificial turf products at competitive prices. Our warehouse carries the most advanced synthetic grass products available, engineered to look and feel like real grass. Every turf product is made with high quality materials that are safe for everyone, especially children and pets.

Industry Leaders

SGW San Luis Obispo has always stood out among competitors, offering new products with the latest technology.

Service Oriented

The only thing better than our grass is our customer service. Our staff is committed to providing the best experience possible for our clients.

Quality Driven

At SGW San Luis Obispo we only offer products that maintains a high standard of quality. Backed by up to a 15 year warranty, the best in the industry.